In the fast-paced digital world, our laptops, smartphones, and other smart electronics have become indispensable. Whether it’s for work, entertainment, or business, we depend on our devices every single day. But what if your laptop could predict when it’s about to fail—and fix itself before the problem even happens?

Welcome to the future of predictive device maintenance, powered by Artificial Intelligence (AI). This emerging technology is revolutionizing the world of electronics repair and maintenance, and Smart Electronix is at the forefront of this transformation in Australia.

What Is Predictive Device Maintenance?

Predictive maintenance is a smart system that uses AI algorithms, sensors, and data analytics to monitor device performance in real time. Instead of waiting for something to go wrong, the system can anticipate failures—from battery degradation to overheating motherboards—and take preventive action.

In other words, your device learns from its own usage data. It tracks temperature spikes, performance drops, unusual current draws, and other metrics to detect early warning signs. When potential issues are identified, the system can alert users or even automatically adjust operations to avoid damage.

This isn’t just futuristic thinking—it’s already happening. In 2025, tech innovators and service centers like Smart Electronix are using AI insights to repair devices smarter, faster, and more sustainably.

Why Predictive Maintenance Matters

1. Fewer Unexpected Breakdowns

One of the biggest frustrations for laptop or phone owners is a sudden malfunction. Whether it’s a dead battery, a cracked screen, or an overheating issue, breakdowns usually come without warning.

With predictive maintenance, devices can detect early signs of stress and inform users before a failure occurs. For example, your laptop might notify you that its cooling system is underperforming and needs cleaning or fan replacement—before it overheats and causes permanent damage.

This means fewer emergency repairs and a longer device lifespan.

2. Cost-Effective Repairs

Traditional repair often means reacting to damage after it happens—sometimes when it’s too late to save expensive parts. Predictive systems help prevent costly damage by identifying problems early.

For instance, replacing a battery when it first shows signs of wear is far cheaper than fixing the entire power circuit after a short-circuit failure. At Smart Electronix, this proactive approach allows our technicians to perform timely repairs that save both money and hassle for customers.

3. Enhanced Device Performance

When laptops or smartphones operate under stress for too long, performance dips—apps lag, systems crash, and components wear faster. Predictive AI continuously analyses usage data and keeps the system optimized.

It can even schedule maintenance tasks such as battery calibration, thermal management, or software updates at the ideal times. The result? Faster, more reliable, and longer-lasting devices.

4. Sustainability and Environmental Impact

Predictive maintenance isn’t just good for users—it’s great for the planet. By reducing device failures and extending product lifecycles, AI-driven maintenance significantly cuts electronic waste (e-waste).

In a country like Australia, where millions of electronic devices are discarded each year, this technology supports the move toward sustainable repair practices. Fewer replacements mean less raw material extraction, lower carbon emissions, and reduced landfill waste.

At Smart Electronix, sustainability is part of our DNA. Our focus on long-term device care—using genuine parts, expert diagnostics, and eco-conscious repair—aligns perfectly with the predictive maintenance revolution.

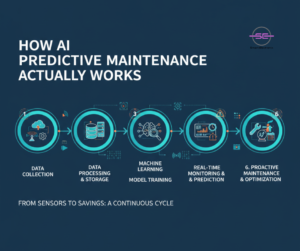

How AI Predictive Maintenance Actually Works

Predictive maintenance relies on a combination of data analytics, sensors, and cloud-based AI learning models. Here’s a simple breakdown of how it functions in a device like a laptop:

-

Data Collection – Sensors monitor temperature, voltage, battery charge cycles, fan speeds, and more.

-

Real-Time Analysis – AI algorithms process this data continuously to identify abnormal patterns.

-

Early Warning Detection – When performance deviates from normal, the system sends alerts or notifications.

-

Automated Adjustments – In advanced systems, AI can adjust power usage, fan speed, or CPU performance to prevent damage.

-

Maintenance Scheduling – Users receive smart reminders to replace parts like batteries, SSDs, or thermal paste before failure occurs.

By integrating this approach into laptop and device repair, Smart Electronix ensures customers enjoy peak performance and reliability for longer periods.

The Smart Electronix Approach to AI-Driven Repairs

At Smart Electronix, we believe the future of repair lies in predictive intelligence. Our technicians don’t just fix problems—they anticipate them. By combining experience, diagnostic tools, and AI-based analytics, we’re redefining the meaning of proactive device care.

Here’s how we’re embracing predictive maintenance:

-

Advanced Diagnostics: We use smart diagnostic software to evaluate component health and predict potential issues.

-

Preventive Battery Replacement: We analyze battery cycles and voltage patterns to replace batteries before they degrade completely.

-

Cooling System Optimization: Our repair process includes fan efficiency checks and thermal analysis to prevent overheating.

-

Data-Driven Service Scheduling: Based on usage history, we recommend when to clean, recalibrate, or service your laptop for optimal performance.

-

Genuine Parts Assurance: All replacements are made with genuine, high-quality parts to ensure long-term reliability and safety.

This AI-supported workflow allows us to deliver faster, smarter, and more transparent repairs for Australian customers who depend on their devices every day.

The Broader Impact on the Repair Industry

AI-powered predictive maintenance is changing the way the entire repair industry operates. Instead of being reactive, service centers are now becoming partners in device lifecycle management.

Imagine this: you bring your laptop in for a check-up, and instead of waiting for a part to fail, the technician tells you, “Your hard drive has a 10% chance of failure within the next 90 days. Let’s back up your data and replace it now.”

This level of precision and foresight doesn’t just improve customer satisfaction—it builds trust. Repair shops that embrace predictive technology, like Smart Electronix, are positioning themselves as the future leaders of the electronics service industry.

Challenges and the Road Ahead

While the benefits are huge, predictive maintenance also comes with challenges. It requires strong data privacy measures, access to manufacturer diagnostics, and skilled technicians who understand both hardware and software analytics.

But as AI becomes more accessible and standard across devices, these systems will only grow smarter. By 2025 and beyond, most high-end laptops, smartphones, and even home appliances will likely come equipped with built-in predictive maintenance features.

The key is to have local repair experts—like Smart Electronix—who can interpret that data and turn it into real, actionable care for your device.

Final Thoughts

Predictive device maintenance marks a turning point in how we manage our technology. Instead of waiting for our laptops to fail, we’re moving toward a world where they maintain themselves.

For Australian consumers, this means fewer breakdowns, better performance, and lower costs. For repair professionals, it’s an opportunity to offer smarter, more efficient services. And for the planet, it’s another crucial step toward sustainability.

At Smart Electronix, we’re proud to lead this evolution—combining expert repair with forward-thinking AI insights to keep your devices running at their best, long before trouble begins.